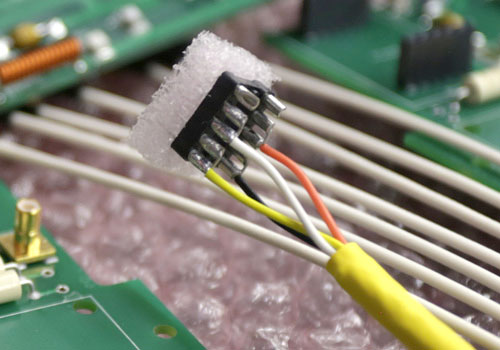

Cable & Harness Assembly

CABLE & HARNESS GROUP

Our Cable and Harness Assembly team is ready to apply their experience, technical knowledge and superior process capabilities to produce the highest quality product on time.

All cable and harness assemblies are built to IPC 620 Class II or III depending on customer requirement

MADE TO YOUR EXACT SPECIFICATIONS

Beginning with a formal New Product Introduction (NPI) review, our team ensures your product is manufactured to your specifications.

Product configuration is tightly controlled by the customer’s part number, revision, and approved vendor list (AVL).

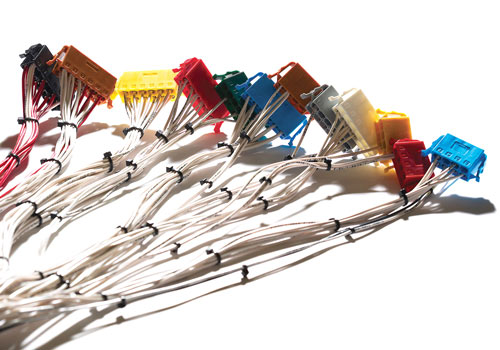

OUR WIRE, CABLE & HARNESSES

We stock a large variety of wire, cable, terminals and connectors.

Production Engineering performs a careful review of each order to assure that the specified wire, terminals and tooling are complementary.

Templates and harness boards are designed from blueprints or samples to assure production consistency.

QUALITY INSPECTIONS AND TESTING

Quality is integrated into the process and issues performance reports to management for analysis and continual improvement.

Full testing capabilities including Hypot, continuity, and functional test.

On staff certified instructors train our operators to the latest IPC-620 class II, class III and J-STD-001 and J-STD-001-ES standards.

We offer complete cable and harness engineering support for Design for Manufacture (DFM) and Design for Test (DFT) capabilities.

Process excellence and competitive pricing make Arc-Tronics the best value for your cable and harness assembly needs.