By Christine Knauer for Avionics News

Republished with permission from the March 2016 issue of Avionics News Magazine, a monthly publication of the Aircraft Electronics Association.

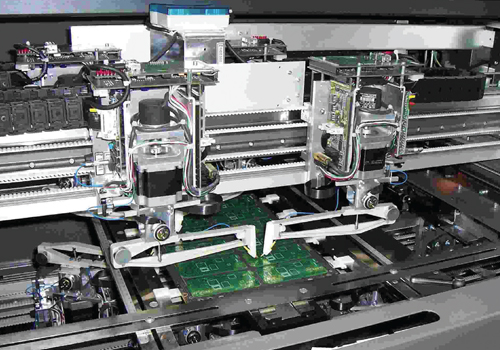

In a bustling business park not far from Chicago’s O’Hare International Airport, Arc-Tronics produces many of the basic building blocks of modern technology – printed circuit boards, cables and harnesses, and box build assemblies. The family owned business manufactures products utilized in aircraft and avionics, medical devices and industrial equipment.

“The products we build end up going into airplanes and installed at airports for landing airplanes, helicopters and military vehicles,” said Michael Goeringer, president of Arc-Tronics and son of the company’s founder. “They go into MRI medical devices, laboratory equipment, and many other industrial applications.”

When Conrad Goeringer started the company in 1972, he built power inverters and power supplies for Tripp Lite and Trippe Manufacturing. Throughout the years,

Arc-Tronics has expanded its capabilities, serving more industries and more customers with a broader product mix. “The company was located in a small basement

building next to Cubby Bear Lounge kitty corner to Wrigley Field,” Goeringer said. “In 1976, Arc-Tronics moved to Elk Grove Village, Illinois, home to the largest

industrial park in the U.S. In 1980, we moved to our current location.”

Today, Arc-Tronics has grown to 150 employees with a second generation of Goeringers – Michael, Mark, Matthew and Marla – managing the business. The company manufactures some 2,500 different types of printed circuit boards, cables and harnesses, and box build assemblies, totaling more than 400,000 assemblies annually.

“Philips Medical is our largest customer, and we build more than 400 different PCBs used in localized MRI machines,” Goeringer explained. “The devices plug into a full-size MRI as an accessory, giving you an MRI image for your ankle, knee, wrist, et cetera, without going through the MRI machine itself. Our second-largest customer is Selex ES (an electronics company based in Italy and the U.K. that provides air, space, land and marine systems). We build printed circuit boards, cable and harnesses, and box builds for the NextGen project for the FAA.

As a contract manufacturer, Arc-Tronics doesn’t create its own proprietary products. Instead, its team of specialists provides comprehensive engineering support and service, including creating prototypes and end products, to customers’ specifications. The company handles all aspects of the production – development and

design, procurement through manufacturing, assembly and delivery – in its two facilities totaling 50,000 square feet. Customers retain ownership of all custom engineering and products, including patents, developed by the Arc-Tronics team.

In 2011, the Chicago Tribune named Arc-Tronics a top 100 place to work in the state of Illinois. The company recently received its AS9100 recertification. “With our AS9100 certification, we are growing our aerospace business,” Goeringer said. “Where our aerospace business was less than 5 percent in 2010, it is now as high as 30 percent of our business, and we continue to grow in the aerospace market.”

The biggest challenges facing the company stem from regulations and issues pertaining to restriction of hazardous substances, as well as conflict minerals such as tin, tantalum and gold mined in countries where revenues may be financing abusive and dangerous armed militias. Not all of the company’s challenges are as serious. One interesting trend keeps Arc-Tronics and its engineers busy innovating.“Things continue to get smaller,” Goeringer said. “We are placing 1005 chip components that are smaller than a speck of pepper.”