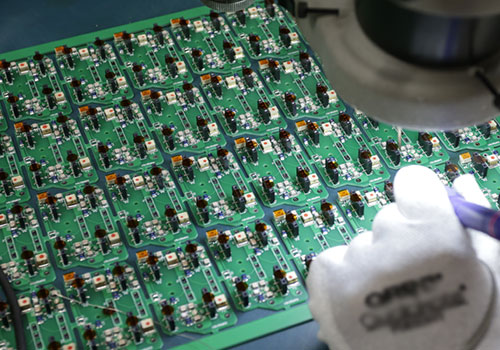

Printed Circuit Board Assembly

PCB ASSEMBLY GROUP

Our PCB Assembly team is ready to apply their experience, technical knowledge and superior process capabilities to produce the highest quality product on time.

All printed circuit board assemblies are built to IPC 610 Class II or III depending on customer requirements.

Beginning with a formal New Product Introduction (NPI) review, our team ensures your product is manufactured to your specifications.

Product configuration is tightly controlled by the customer’s part number, revision, and approved vendor list (AVL).

Quality is integrated into the process and issues performance reports to management for analysis and continual improvement.

STATE-OF-THE-ART EQUIPMENT

- Fully Automated Screen Printers with 2-D vision.

- Inline 3-D Solder Paste Inspection (SPI).

- Fully Automated Pick and Place Equipment capable of placing 01005 chip components and micro-BGA’s.

- Automated Optical Inspection (AOI) is performed on all surface mount components.

- Off line programming and quick change feeders allow for the utmost efficiency and flexibility in job change over.

- 3-D X-Ray for BGA and QFN components.

- Quick-change feeders for job flexibility.

- Dedicated lead and lead-free Selective Solder and Wave Solder equipment.

ENGINEERING SUPPORT AND TESTING

Full testing capabilities, including In-Circuit Test (ICT), Flying Probe, JTAG, and functional test.

On staff certified instructors train our operators to the latest IPC-610 class II, class III and J-STD-001 and J-STD-001-ES standards.

We offer complete PCB engineering support for Design for Manufacture (DFM) and Design for Test (DFT) capabilities.

Process excellence and competitive prices make Arc-Tronics your 1st choice for printed circuit board assembly.